When the curiosity of a Vibration Issue Pays Off

When the curiosity of a Vibration Issue Pays Off

Case History by Robert Smith

Primary

Regrind Mill Broken Gear

Introduction

I had only been in my

Reliability Superintendents role for a few months and I was in the process of

setting up a Vibration Analysis Program. This involves looking at all plant

locations and the critical of equipment.

As I was inspecting the

exterior of this vertical mill gearbox I could hear what I would describe as a clicking

sound. The sound did not sound like a high-energy impact but I was curious. I

asked a maintenance person working in the area who explained the clicking noise

had been there for a while and they did not think it was an issue. The

vibration database was not set up at this time for this area of the plant.

To get a reasonable idea of

the frequency of the impacts I used a stopwatch. I would count 50 low energy

impacts and stop the timing. The timing would vary and remember I was only

doing this for basic information. The 50 impacts would be counted in 19.3

seconds. 19.6 seconds etc. So 2.6 to 2.5 impacts per second. So we are looking

at the rotating part in question at approximately 158 CPM or maybe slightly

higher. This information was used to assist in setting the frequency range for

vibration measurement to determine the cause.

REGRIND

MILL GEARBOX

The next step was to look

through the OEM manual. I calculate the second reduction of this gearbox was

rotating at 160 CPM. I set up this machine in the vibration database to cover

velocity and acceleration in both spectrum and time waveform. There is one

reading, demodulation, or enveloping that is sensitive to low energy impacts. I

set the demodulation /enveloping to take both spectrum and Time Wave Form

Findings

The vibration data analyzed

in velocity and acceleration appeared normal. Taking demodulation Time Waveform at the second reduction stage indicated low energy impacts were evident

at approximately 160 CPM The impacting energy levels were low.

From the drawings of the

gearbox there appeared to be a reasonable distance between the second

reduction gearing rotating at 160 CPM and the casing. Then there was the

thickness of the casing itself. Were these factors masking the true energy of

the impacts?

Inspection

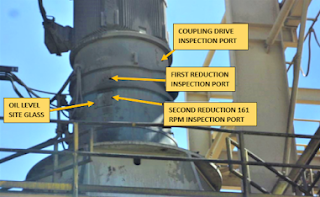

As can be seen from the

picture above there is an inspection port at the second gear reduction. A works

order was submitted to inspect the gearbox's internal gearing at the next

scheduled shutdown.

The Mechanical Supervisor

called me when the hatch was opened and said “You have to see this” There was

one gear tooth completely sheared off. By luck when the Mill has shut down the

view of the broken tooth was directly in line with the inspection port.

The

teeth on the rest of the gear looked in immaculate condition.

View 1 broken gear tooth

View 2 broken gear tooth

Conclusion

Vibration analysis is a great tool in any predictive maintenance program. If vibration data indicates an issue and the

It should mention that

demodulation /enveloping is very sensitive to low energy impacts. In relation

to bearings, subsurface defects can be picked up. All other vibration data

should be analyzed before making an assessment or recommendation.

In this instance

demodulation / enveloping proved to be the best parameter.

I hope this article will assist people new to vibration analysis.

Contacts

Email: robbieccs@gmail.com

Comments

Post a Comment